Stihl TS 500I

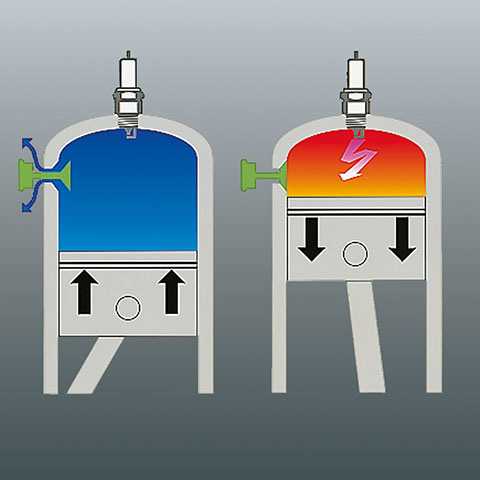

STIHL 2-MIX Engine

The new 2-MIX engine features an advanced stratified charge system that boosts power, whilst reducing consumption and pollution, significantly lowering unburned hydrocarbons in the exhaust. The result is a cleaner, more fuel efficient engine

Long-life air filter system

The long-life air filter system with cyclone air routing ensures that 80% of dust particles are separated and transported out into the surrounding air. In turn this extends the cleaning intervals for the foam pre-filter.

STIHL Anti-vibration system

Buffer and spring elements reduce the transmission of engine vibrations to the operator’s arms and hands. This makes free-hand cutting much less strenuous.

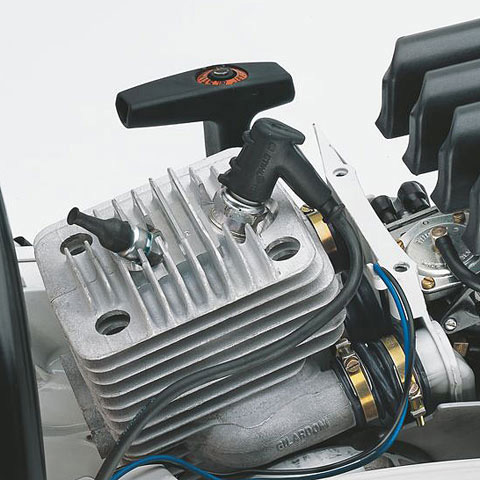

Decompression valve

The decompression valve is part of the easy start-system. The valve reduces pressure in the cylinder which means less effort is required to start the engine.

Manual fuel pump (Purger)

If your petrol driven equipment has a manual fuel pump, you can reduce the number of starting strokes by about 40% if you operate the pump a few times before starting up. This speeds up the supply of sufficient fuel to start up

Compensator

This controller in the carburettor prevents the fuel-air mixture getting richer as the air filter becomes clogged. The correct quantity of fuel is delivered to the carburettor depending on the quantity of air passing through the air filter. This keeps the fuel/air ratio in the combustion mixture constant and hence also the engine power. The filter doesn’t need to be cleaned until an appreciable drop in power occurs.

*Specifications are subject to change without notice.